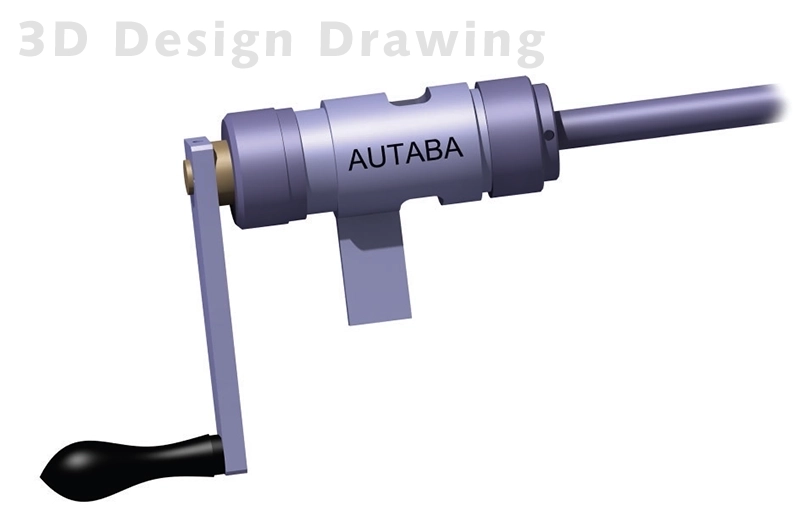

Coning of Tubing Ends Autaba Hand Tools

Special Angle cone cutting hand tools 58°-59° coning.Coning of tubing ends with AUTABA double cutter

Products Introducation

1. Cut tubing to length and square off the end using hacksaw with at least 32 teeth per inch or abrasive cut-off wheel. Allow extra length for proper engagement into the connection as listed in design table Additional 1/16" should be added to each end to compensate for coning/end facing. Note: When cutting tubing with abrasive cut off wheel, tubing should not be over heated effecting material properties.

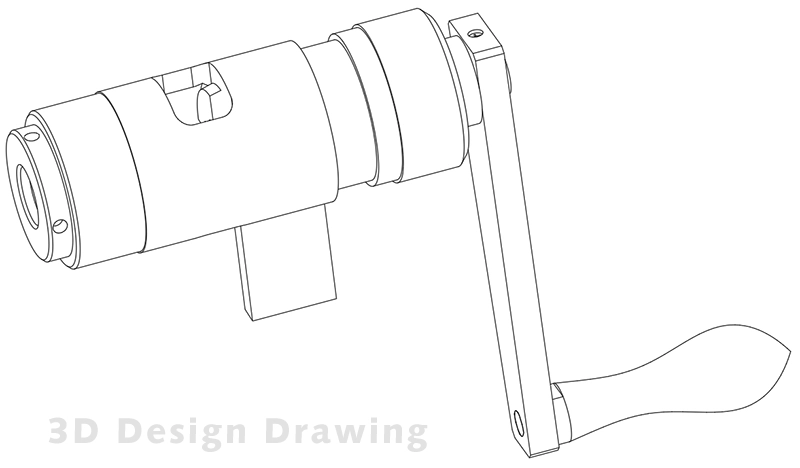

Mannual Kits Procedure

2.Install the collet and collet nut into the bottom of the coning tool housing. Remove the cutter support feed nut from the coning tool housing and install the cutters. This can be done by backing out the four set screws in the cutter support. Note: When installing new blades, be sure the blades are flat against the holder.

3. Place the coning tool housing (or optional support arm), without the feed nut/cutter support assembly, in a vise. The vise should be equipped with soft jaws, and the housing should be placed in the vise to allow lubricant to flow to the cutters and cone.

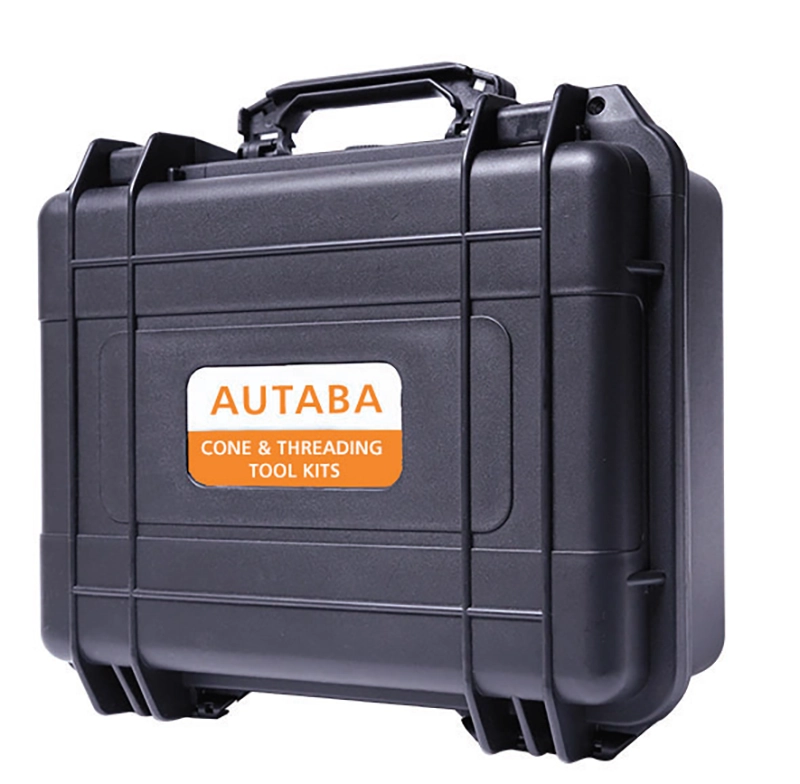

Tool Kits Package

Manual Download:

Thread dies and taps;

Coning of tubing ;

Test assistance tools

Calibration assistance tools

Hand soldering assistance tools